Shakambhari Group comprises of 5 units all over West Bengal.These units have been modernized with the highest level of technology absorption viz. Dri Kilns, Ferro Alloys, Steel Melting Electric Arc Furnace, Continuous Caster, 3 Fully Continuous Rolling Mill with Belgium Designed Tempcore Technology and German Designed Thermex Technology. The group is also interested in Ground Field Expeditions, acquiring new places to builtup modern technology. With more than two decades of experience in the manufacturing of iron & steel, we focus on achieving excellence everyday. Deploying the best industry expertise, providing them with high quality raw materials and state-of-the-art technology, we deliver only high quality products with no compromise.

Iron Pellets

Iron pellets are small balls of iron ore used in steel production. Iron ores undergo a pelletizing process that combines mixing of raw materials, forming the pellet and thermal treatment baking. The process converts soft raw pellets into hardened balls of approx. 8 to 16mm diameters that are uniform in size and used as feed in Blast Furnace, Electric Arc furnace or DRI plant.

Iron pellets usually have high porosity which makes the reduction process quicker in the blast furnace. The spherical shape and open pores offer greater permeability which results in easy furnace operations. High pellet strength offers greater resistance when it comes to disintegration during the descent of burden.

Iron pellets are an integral component of steelmaking. From the construction of bridges to transport vehicles, planes, household appliances and many other infrastructures – steel is used in multiple industries and makes up much of the world around us. It has a great role to play in the advancement of developing nations which is continuously pushing the demand upwards.

Iron Pellet USP

Pellets are a type of agglomerated iron ore fines which has better tumbler index when compared with that of parent iron ore and can be used as a substitute of lump ore for the production of sponge iron and in blast furnaces for the production of hot metal. The iron pellets are produced with cold crushing strength (CCS) of 210+ and porosity of 24+” which helps to maintain grade in DRI fem – 80+ and our product mean particle size (MPS) is ~9.5-10 which assists in reducing oxygen in kiln and maintain consistency in grade. Iron Pellets are used as raw material for sponge iron and blast furnace.

Elegant can produce various grades/quality of pellet because of having rotary kiln where the pellets are heated and fired uniformly. The process can use multiple ores simultaneously by applying the art of raw material blending. Pellet process helps save energy i.e. power because of excellent heat recuperation and lower drop in pressure of gases. Apart from using items as input for our finished products.

Sponge Iron

India is the largest producer of sponge iron in the world with a host of coal-based units located in the mineral-rich states of the country. Sponge iron is produced primarily through the coal-based method of production. Sponge iron is also known as Direct Reduced Iron (DRI) and is widely used in the steel industry as a primary raw material in induction and electric arc furnaces. Over the years sponge iron, a significant raw material for producing high-quality steel.

Sponge iron or DRI is produced from the direct reduction of iron ore to metallic iron in the form of lumps, pellets or fines. Sponge iron is a metallic product with consistent chemical and physical characteristics. Iron ore pellet is used for reduction and after reduction, the product resembles a sponge for the pores left behind after removal of oxygen. That’s why it is called sponge iron. The process of manufacturing sponge iron aims to remove the oxygen from iron ore. At Shakambhari, we use both iron ore (4-25mm) and pellet (round balls shaped of 5-18mm) as feed material for producing high-quality sponge iron. We have an integrated steel plant where sponge pellets are mostly produced for captive consumption at our Steel Melting Division. We produce high graded sponge pellets with low Sulphur content that are mainly used for manufacturing high-quality QST bars and Wire rods.

MS and CRS Billets

Billets are semi-finished casting steel considered to be one of the best raw materials for producing high-quality steel bars and structural products. Billets undergo a series of manufacturing processes to be converted into a variety of finished steel goods, suitable to be used for various purposes. Billets are extensively used in forge shops and machine shops for the production of engineering goods, or feedstock in the rolling and other metal-processing operations.

Billets are produced with various grades and variants such as Mild Steel, Alloy Steel, Special Steel, Corrosion Resistance Steel etc. MS Billets confirmed to IS 2830:2012 are widely used for the production of construction steel QST bars.

At Shakambhari, the raw materials required for the manufacturing of MS Billets such as – Sponge Pellet or Sponge Iron are produced in-house. The quality control process of raw materials results in the production of the best quality of Billets. Shakambhari has integrated steel plants that produce a wide range of continuously casted billets employing world-class technology. Billets produced are mostly captively consumed as a raw material feed to our Rolling Mills manufacturing QST bars & Wire Rods. Shakambhari also has a niche export market for its high-quality Billets.

M.S Billet USP

- Shakambhari maintains stringent quality checks to produce world-class quality MS & CRS Billets conforming to IS 2830:2012.

- State-of-the-art equipment and modern testing apparatus at our laboratories allow the continuous quality monitoring of production. Chemical analysis is carried out through Spectrometer during melting and at the final stage to assure consistent chemical composition of Billets.

- After casting, Billets are carried out through the physical dimension tolerance test, Sulphur print test, Bend test and Camber test to ensure zero-defect Billets.

- At Shakambhari, the raw materials required for the manufacturing of MS & CRS Billets are mostly produced in-house, ensuring superior and consistent quality.

- Shakambhari has received certification from the Bureau of Indian Standards (BIS) for the production of Carbon Steel Cast Billet Ingots, Billets, Blooms & slabs. The main defining factor of the product is its chemical composition which we follow as per IS 2830:2012 standard.

- Shakambhari billets are used for captive rolling of QST Bars and Wire rods, as well as also being exported to niche markets worldwide, due to preference for its high quality.

Wire Rods

Wire rods are hot rolled round bars of thin section. Hot casted billets produced from a continuous casting system are rolled with state-of-the-art facilities and technology to thick cross-sections and then cooled and coiled into the desired sizes

Shakambhari is one of the leading wire rod manufacturers in India that produce high-quality rods with the promise of dimensional precision. Wire rods produced here conform to IS2062:2011 and pass-through tensile test, elongation test, bend test and re-bend test before dispatch to its esteemed customers. The technical parameters of wire rods are majorly determined by the grade of Billets they are produced from, hence fully tested and zero-defect billets confirming to IS2830:2012 are only employed for the production of wire rods. MS Billets are manufactured in our integrated steel plant assuring stringent chemical composition and other quality norms.

Wire Rod USP

- At Shakambhari, we have an integrated steel plant and hence have the edge on controlling the quality from the very beginning stage of basic raw material, then crude steel making.

- The raw material required for the manufacturing of wire rods is MS Billets that are produced at integrated steel plant assuring stringent chemical composition and other quality norms.

- The MS Billets are directly hot charged to State-of-the-art automatic Rolling Mills to produce world-class quality wire rods. Direct hot charging of billets ensures minimum cross-sectional tolerance and lesser carbon footprints.

- Laboratories are equipped with computerised machinery and modern testing handles, ensuring the quality monitoring in-line and post-production of the product.

- We are producing wire rods of sizes 5mm to 12mm conforming to IS2062:2011.

- We have received certification from the Bureau of Indian Standards (BIS) for the production of High Strength Deformed Steel Bars & Wires for concrete reinforcement.

Construction Steel

ELEGANT STEEL QST 550D

Elegant Steel was introduced in the year 1993 as a brand name of SPS Steel Rolling Mills Ltd. Elegant Steel are premium quality high yield strength reinforcement steel by Shakambhari Group manufactured at its Integrated Steel Plant using primary steel making route. The ‘Elegant’ brand along with SPS Steel plant was acquired by Shakambhari Group in April 2019 as a flagship brand. Elegant Steel now comes with the grade 550D which ranks highest among the most trusted steel bars for its features being perfectly blended with high tensile strength, extra ductility, easy bendability, uniform rib patterns, earthquake, fire and corrosion resistant, cost effective. Elegant Steel QST is widely approved by many Governments and Semi-Governments Departments. The brand is now Green Pro certified by CII making it more sustainable for years. Shakambhari Group has enhanced the brand strength with the increased production capacities to 3 times pre-acquisition, expanding the brand reach PAN INDIA.

THERMOCON TMT 500D

Thermocon is a flagship brand of Shakambhari Group which was launched in 2016. It comes with a grade of 500D with features of earthquake, corrosion, fire resistant, superior strength, high elongation, strong grip, cost effective. The brand is widely approved in many Government and Semi – Government and is widely used for High Rise Building, Flyover, Bridges, Highways.

Binding Wires

Binding Wire is made of mild steel wire rods through the cold drawing process. This is a value added product that has a huge demand in retail market.

Binding wires are used for tying applications in construction sites and thus, need to be flexible enough to fit the multiple usage needs repeatedly. Due to its tensile strength and ductility, the wires can be easily bent and tied in a knot without any breakage. They help in holding lapped bars in the ideal position and pouring the concrete into the frames without dislocating the rebar.

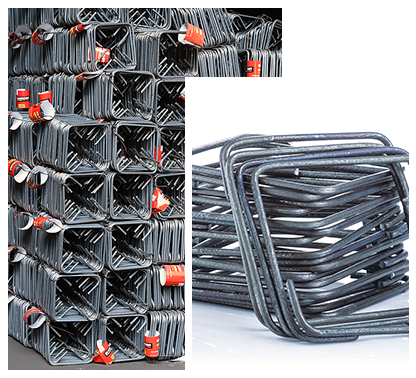

Link Easy

Link Easy are also value added products. These are mainly used to hold the main bars together for lateral support to the main structure. It is a closed loop of reinforcement, made of rebar that can be of varied sizes depending on the design and shape of the load-bearing structure. At Elegant Steel, we produce quality Link Easy made of high strength, ribbed QST bars.

Contact With Us

Feel free to contact us today !! Our team is ready to help you instantly !!